Kyle Haskett, PE

Associate

Kyle received both his Bachelor of Science in Architectural Engineering and Master of Science in Civil Engineering-Structural Emphasis from the University of Oklahoma. He is…

View Profile

In the AEC industry, we do our best to get things as perfect as we can.

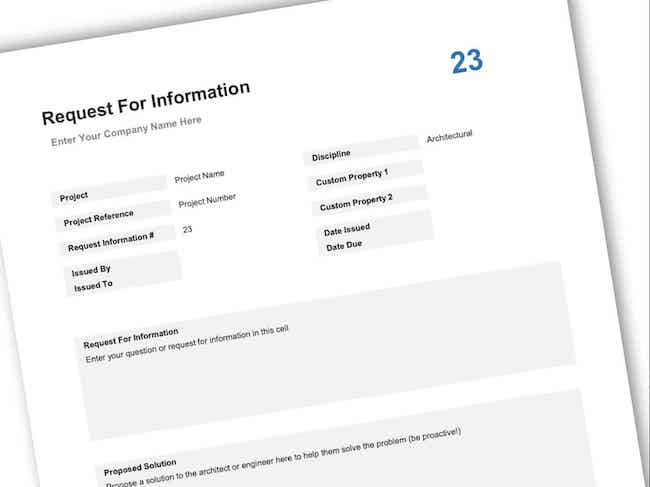

Despite our best-efforts, things do not always turn out the way you plan for them to. One of the ways we have of dealing with the real-world clashing with our plans is through the “request for information” RFI process.

Typically, the real world has its own plans that don’t always allow for our plans to happen as we intend them. When this happens and something hasn’t gone quite as we intended, the contractor will submit an RFI to allow the design team to assess the as-built condition and design a new way for the contractor to proceed.

As an engineer who deals a lot with existing construction where we don’t always have existing or as-built drawings, RFI’s are expected since we can’t always fully determine existing construction from our site visits. We do our best to assume the construction for our design documents but must rely on the contractor to report back to us what the construction actually is once they have it opened up in the demo phase.

RFI’s are going to happen, but as an engineer, making sure you get the right information up front can keep a project moving and avoid miscommunications and frustrations down the line. In my experience, what makes a good RFI is broken into 3 components:

Quality photos Marked up drawings identifying the base issueSuggested solutions from the contractor• Quality Photos

First off is a good photo of the issue. A photo is worth a thousand words! This might seem like a simple idea but getting the right photos is very important. Since my projects are generally not in the same city as I work, I am not in the field and must rely on the contractor to get me the information I need to design a new workable solution.

I recently had a conference call with the whole AEC team as well as the client for one of my projects where the contractor described exactly what was in the field. After this call I was certain I knew what was built based on what they had described. I sent a sketch of my understanding to verify we were all on the same page, and to propose my solution. I quickly got a photo back that was the opposite of my understanding. The problem came about because the contractor used some terms that have very specific engineering meanings (which is why proper use of structural engineering terms is important!).

What makes a good RFI photo? There usually isn’t a single photo that can accurately depict the information I need. I always tell contractors I need a global and local photo of the issue. The global photo is from farther away and gives context to the issue. This allows me to put the RFI issue in a greater framework and gives me a better understanding of what is happening with the structure. The local photo is a close-up photo that gives the details of the issue at hand. Usually if a photo comes in with the RFI, it’s the local photo because it isolates the issue.

Want more tips? Read our blog on how to take better field photos!

• Marked-up Drawings Identifying the Base Issue

Next up, marked-up drawings with the base issue identified makes up a good RFI. Something a photo can have trouble with is the dimensions. Sometimes it’s difficult or impractical to get a tape measure included in the RFI photo, so I ask the contractor to mark up our plans or associated details with the field measurements of the as-built condition.

I also have received RFI’s that state, “the problem is my steel is too long.” Once I start getting more information from the contractor, it is determined that the steel is too long because the anchor bolts were misplaced. These get to be tough RFI’s because it’s easy to accept the steel is too long and respond with how to shorten the beam and get it reconnected into the structure. But then days or weeks later, more RFI’s come in because none of the other steel associated with this area is fitting up either. It becomes a compounding RFI and now we have even more problems because we have already addressed the wrong items in previous RFIs.

Marking up documents can help head this problem off because we are putting the issue in the greater context of the building structure itself. It can help us get to the root cause.

• Suggested Solutions From the Contractor

The last component to a good RFI is a suggested solution from the field. Usually, I receive an RFI that states a problem and asks how to proceed. Early in my career, I would gather all the information needed and submit a proposed solution only to get a call from the field asking if they can do it a different way. While I loved having the contractor engaged in the solution, it was tough when you spent the time to devise a good solution then have the contractor suggest what they really want to do. It felt like a bit of a waste of my time, so now that’s something I like to bring up while I am in the initial stage of information gathering.

I like to ask the contractor directly, “Is there a solution you would like to look into first?” The contractor is in the field and will have good insights into what they can do. The next question I like to ask is, “Do you have any extra material on site that you would like to try and use?” I don’t have any problem specifying a less efficient component size if the contractor has some on site and doesn’t have to wait for new material to be delivered to the site.

The only RFI I don’t like is the, “We built this wrong two months ago, here is how we fixed it last month, it is now inaccessible due to finishes being in place, is the fix structurally acceptable?” I hate this RFI because if I can’t make the existing fix work, it seems like I am directing more work, delaying the project and costing everyone more money.

So, when the real world throws your project a curve ball, remember to request all the information that you need to make a decision: good photos, marked-up existing plans and details, and a preferred solution. Contractors and engineers make great partners! Clearly communicating what you need and encouraging the on-site experts to tell you what they think can save valuable time and produce an efficient solution.

Are you passionate about the AEC industry? Do you want to use your talents with a group of the greatest engineers, landscape architects, technicians and support personnel in the industry? You've found the right place. Wallace is unique in the way we strive to make lives better for our clients, communities and employees. And we believe we have more fun doing our job than just about anyone else! The art of possibility. Discover it at Wallace.

Learn More

There are no comments.