Kyle Haskett, PE

Associate

Kyle received both his Bachelor of Science in Architectural Engineering and Master of Science in Civil Engineering-Structural Emphasis from the University of Oklahoma. He is…

View Profile

At the start of the year, we developed this blog series to spotlight the various services Wallace offers. On June 1, our 40th anniversary, we rebranded from Wallace Engineering to Wallace Design Collective, a name chosen to reflect not just engineering but all the services we offer. We also refined our company mission from "dedicated to the art of engineering" to "dedicated to the art of possibility." To reflect our growth as a firm, this week we spotlight our cold-formed steel design services.

This week, to reflect this growth, we are spotlighting our cold-formed steel design services.

Who are the Cold-Formed Steel experts?

Let’s meet the team! Rachael Wilkerson is our cold-formed steel design guru. She has been at Wallace for 10+ years and works in the traditional group. Greg Poston and Ron Jantz round out the group with QC reviews and senior leadership. Greg is an Associate within the traditional group with 20+ years’ industry experience. And Ron is a Principal in the traditional group with 33+ years here at Wallace.

Rachael Wilkerson, PE Greg Poston, PE, SE Ron Jantz, PE, SE, Principal

What is Cold-Formed Steel?

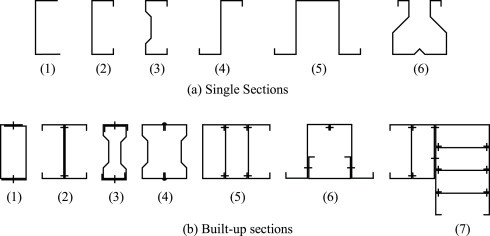

Cold-Formed Steel (CFS) is thin gage structural quality steel sheets that are formed into structural sections by cold rolling. Cold rolling just means that heat is not used to aid the rolling process like is required for thicker steel members. However, because the members are so thin, the shapes fall outside of the AISC design manual. Cold-formed members tend to buckle in ways hot rolled steel does not, affecting the strength and stability of the members, as noted by Rachael.

What CFS services do we offer?

We have performed services to design CFS for single story construction, tenant improvement or buildouts using CFS, and CFS structures above podiums. Another service we offer is design and calculation of deferred submittals. Many times, the main building engineer will defer the CFS design to a specialty engineer for efficiency, through a deferred submittal.

What are some misconceptions of CFS?

A common misconception of CFS is that “you can just pick cold-formed sizes out from a table,” according to Ron. In some instances, it is true that you can pick the correct sizes out of the manufacturer provided tables. However, the tables are set up with pretty basic loading conditions that don’t include many real-world situations.

Another common misconception is that CFS is only good as an architectural feature. CFS is not just a great material for wall construction and facades, it can also be efficient when used for load-bearing walls and shear walls.

But how strong and versatile is CFS when it comes to structures? Surely CFS should only be used for small single-story construction, or as the top story only, right? Not so! CFS has the capability and versatility for multi-story construction. For example, Rachael designed The Winnie on North Winthrop in Chicago, IL which is a cold-formed steel joist and stud structure, comprised of a podium with 4-stories of apartments above. This project was well suited for cold-formed due to the repetitive nature of walls in apartment buildings.

What are the benefits of CFS?

“Cold-formed steel is a very efficient use of material”, says Ron. It’s very lightweight and is easy to cut in the field.

Cold-formed sections typically are connected by screws, which don’t require special certifications to be able to install. Conversely, traditional hot rolled steel often has welded or bolted connections that may require special training or inspections.

According to Rachael, wood is the other structural system usually considered along with CFS; however, CFS has “acoustical and combustibility advantages” over wood.”

Additionally, cold-formed steel is a sustainable product, as it can be recycled.

Overall, cold-formed steel is a wonderful product with many advantages. Next time you are starting up a project consider calling your structural engineer to discuss the use of CFS in lieu of traditional steel or wood. Or better yet give Rachael, Greg or Ron a call!

Are you passionate about the AEC industry? Do you want to use your talents with a group of the greatest engineers, landscape architects, technicians and support personnel in the industry? You've found the right place. Wallace is unique in the way we strive to make lives better for our clients, communities and employees. And we believe we have more fun doing our job than just about anyone else! The art of possibility. Discover it at Wallace.

Learn More

Really interesting.

Thanks for the article. It was great. I’m thinking of translating it into Persian and publishing it on my blog ( https://ahanspot.com ). Is it okay with you?