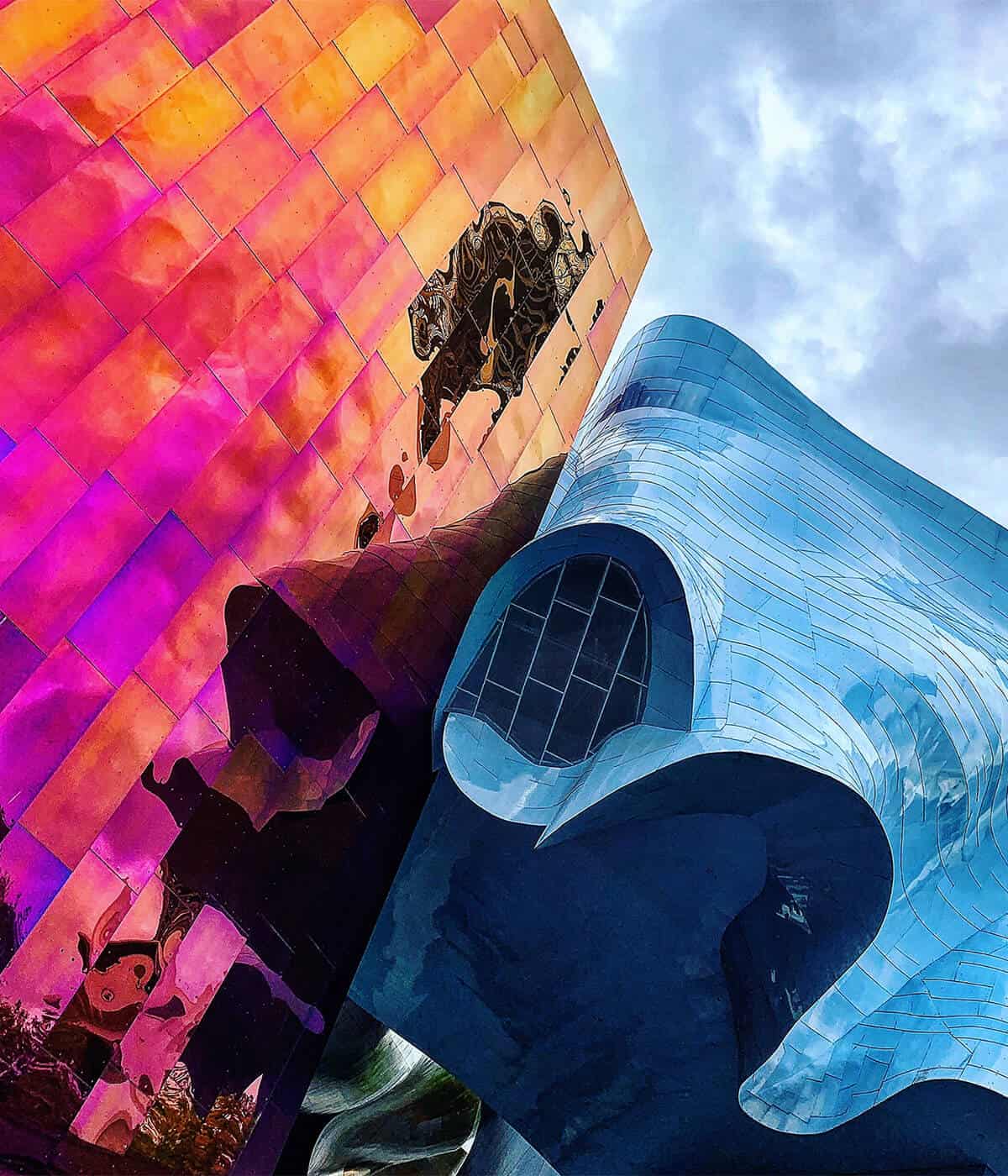

de Young Museum

The de Young Museum’s iconic copper exterior is more than an artistic gesture - it’s a feat of structural engineering, one that required us to chart new territory in bronze design standards.

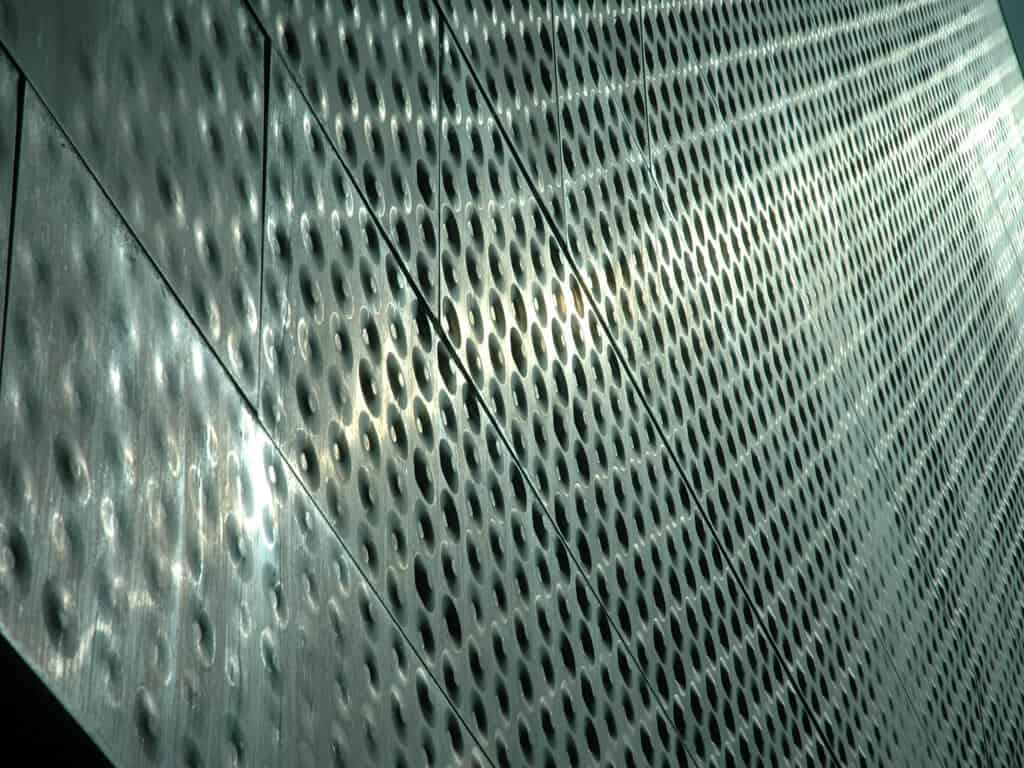

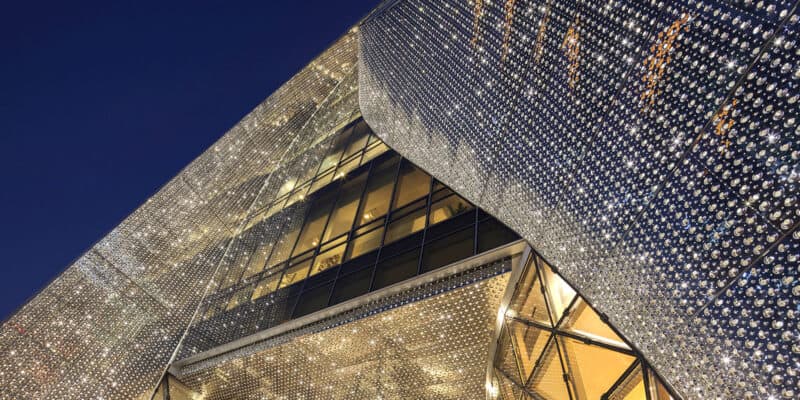

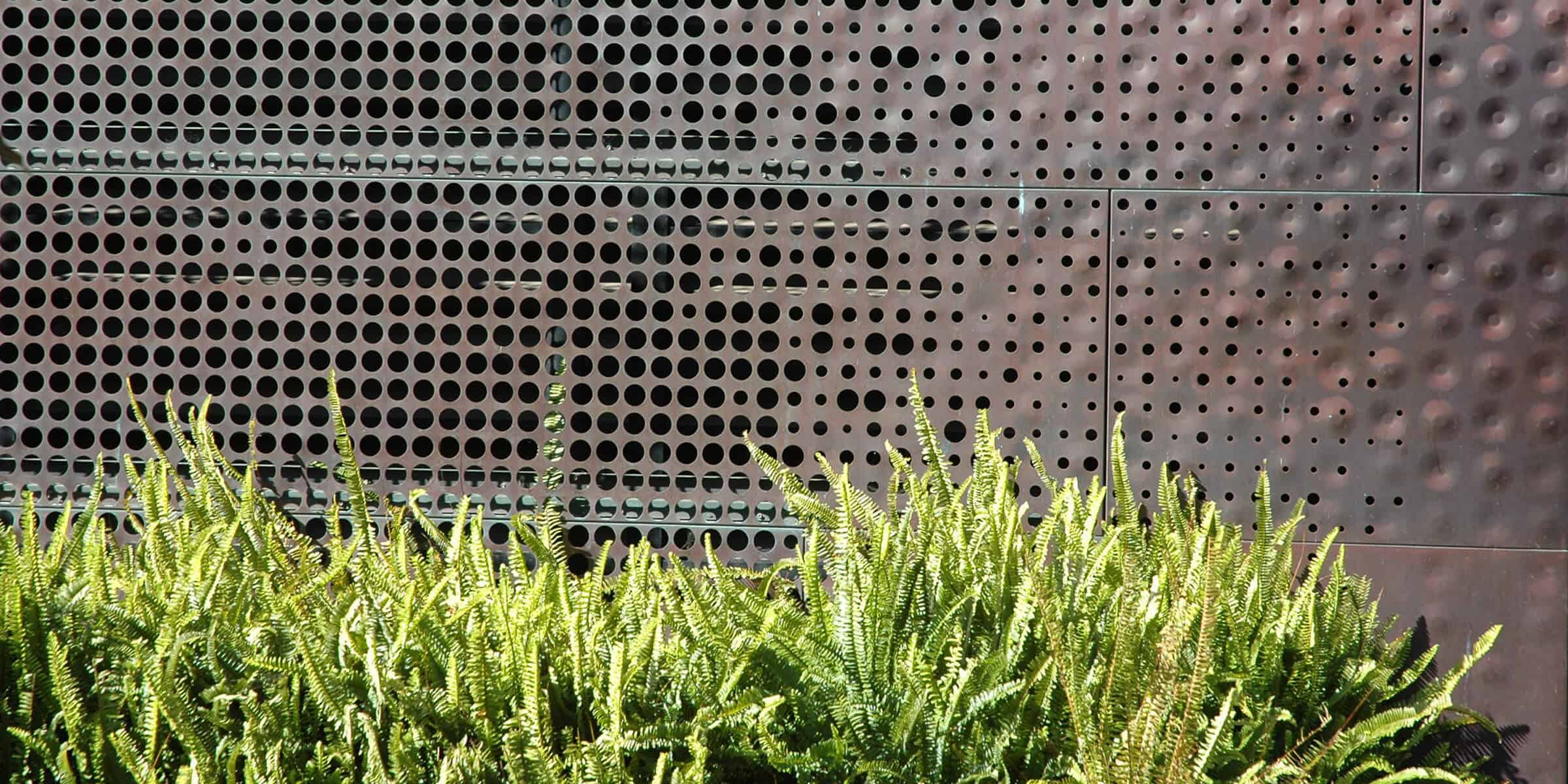

The de Young Museum in Golden Gate Park, designed by the renowned Swiss architecture firm Herzog & de Meuron and Fong & Chan Architects in San Francisco, embraces both art and nature. Constructed of warm, natural materials including copper, stone, wood and glass, the new museum blends with and complements its natural surroundings. The building’s dramatic copper facade is perforated and textured to replicate the impression made by light filtering through a tree canopy, creating an artistic abstraction on the exterior of the museum that resonates with de Young’s tree-filled park setting.

Wallace Design Collective provided structural engineering services for the exterior copper facade system for the museum. The wind girts that support the perforated copper screens on the tower are extruded bronze structural elements.

Although this is not the first time bronze has been used as a structural element, it is the first time the City of San Francisco has reviewed structural calculations of this type. Since there are no design criteria in the Copper Development Association’s Standards Handbook or standards in the International Building Code governing the structural design of copper and bronze elements, we developed our own design standards as part of this project. These were presented to the structural review staff of the City of San Francisco, along with our calculations for the wall panel and skin system. Our calculations and drawings were approved for permit on the first review with no comments from the review staff.

The skin is a perforated and “dimpled” 48 oz. sheet copper wall panel system. The skin on the exhibit building is applied to a cold-formed copper girt system. The panels on the 10-story administration building are supported by steel pipe frames, which are attached to the building frame with a special joint, isolating the panel frames from the building during a seismic event. The joints behave much like the drive shaft in a four-wheel drive vehicle, allowing rotation in two directions as well as elongation in the vertical axis, thus accommodating the large story drift and torsional rotation of the building frame.

photography: ©Don Wheeler

2006 National Council of Structural Engineers Associations – Excellence in Structural Engineering Award in Special Use Structures Category