ORIGIN: Starting the Conversation

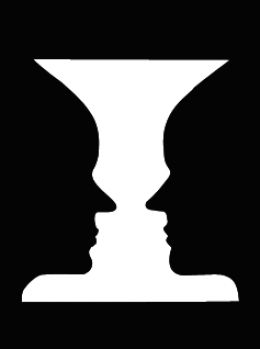

A Different Perspective

Several years ago, I started providing metal stud shop drawings for sub-contractors, and it made me change the way that I detail the construction drawings on the projects that I work on.

When I first started providing the calculations and shop drawings based on other engineers’ performance specifications, I went about it the same way that I would always design a building. I quickly learned that the light gauge clips that I would always use were not the ones that most sub-contractors wanted to use. This happened with almost every part of the connections I was designing. Since I had not dealt with the construction side of the metal stud industry prior to this, I would use the same details I always had without knowing how readily available the certain clips and power-actuated fasteners (PAFs) were. More importantly, from the construction side, was how expensive some of these specialty clips and PAFs were. I quickly got questions from the sub-contractors asking why I did not use certain products over others. My response was that I didn’t know why, other than those were the ones I had always used. They were very kind, and quick in pointing me in another direction to see if these less expensive connection pieces would work for our conditions. Turns out they did, for most cases. Just like the clips, the PAFs I was using were not the same ones the sub-contractor wanted to use. The capacity of the PAFs to steel was rarely a factor, since the two PAFs required to hold the clips in place were way over the capacity needed. Although this was not an issue on connecting to steel, there were issues when trying to connect to concrete. The strength of these PAFs into concrete is very low compared to steel. Options for these would be to use different PAFs, but those were not the ones they had in stock. Another option is to make the embedment into the concrete longer. The problem I had heard, was when you embed the PAFs more than an inch, there were frequent issues with the first charge not embedding the anchor all the way into the concrete. So, I guess you give it another charge to finish off the embedment, but this would often lead to creating issues with the track at this point. Now, that I cannot change the embedment or the type of PAF, the other option was to add more PAFs per connection. Sounds easy enough, but this sometimes meant several PAFs in one location, but then you start to have edge distance issues and spacing issues to be able to get the full capacity. I was also quickly informed that some of the sub-contractors would like to detail their wall opening differently. Some would prefer to use the same gauge of studs as the wall was using, and just build up several together to get the capacity required. While others preferred instead, to use fewer heavy gauge studs. I have learned a lot about the different options, and keep learning new and more cost effective solutions for these designs, because of this shop drawings process.

While providing these shop drawings I have seen drawings from several architectural and engineering firms in Oklahoma, as well as from out of state working in Oklahoma. I’ve seen sets of construction documents that detail the building, and coordinate between the architectural and structural drawings. That is not often the case though. More often, the structural and architectural drawings do not coordinate, and quite frequently, the structural drawings don’t show metal studs at all. This gets frustrating and it doesn’t seem to be getting any better. So it’s just something I’ve gotten use to over the years. This is one thing I really appreciate about the drawings that Wallace Engineering produces. We go through great lengths to try to make sure that our drawings coordinate with the architectural drawings. This isn’t always easy, but I think this is something that puts us at the front of the pack when it comes to structural engineering firms in the area.

While providing these shop drawings, it has made me more aware of all the complexities that the specialty engineers have to deal with on a daily basis. It is such a relief when I open a new set of drawings and actually see the drawings coordinated.

With seeing all of the different sets of drawings over the years, and all the issues I’ve had trying to interpret non-coordinated drawings, and to assume I’m detailing these shop drawings how the architect and engineer interpret their own drawings, I know this has made me a better engineer. I take all those issues I’ve come across in the past, and try to eliminate as many as possible when I send out construction drawings of my own. There are many times where the engineer of record has to go back and provide extra steel for the detailed portions to actually work. That is not a simple task seeing how no one wants to spend more money after the project has bid. Coordinating and detailing is an essential part of producing a good set of construction documents, and often it seems that this is not done during the design process. Yes, this does take more time to do during design and time is money, but I feel you save extensive amount of time during construction. This is because there are usually less RFI’s, not always, but more importantly, less change orders. I have seen this to be true on a lot of my projects, and it seems like a much simpler approach to spend a little more time up front, than to try and explain why the owner needs to spend more money during construction.

Through this shop drawing production process I’ve seen the other side of design, and it is more complicated than it sounds. It doesn’t seem like it would be very difficult to design metal studs, but this is a very specialized field. Seeing as the thickness of these members is often less than five hundredths of an inch thick. The design of these thin members is definitely something I don’t want to get into at this point. However, I would say there is a great deal of complexity when designing with these thin members.

To sum this up, a very important and often over looked part of producing a good set of construction documents, is the detailing. As I mentioned before, a detailed and coordinated set of construction drawings, are much easier to interpret. Do not leave it up to the contractor to interpret your set of construction documents. They are not mind readers, and this often leads to deficiencies.

Brandon Wahl is an associate at Wallace Engineering, a structural and civil engineering consulting firm. He can be contacted at info@wallacesc.com. Follow us on Twitter (@WallaceEng) for blog updates.

There are no comments.