“Design” and “problem solving” are terms that typically get associated with engineering. But what about the design and problem solving that go into bringing an engineer’s creative solutions, calculations, and models to life?

Contractors often don’t get the credit they deserve for the innovative masterminding that goes into construction.

For example, it’s certainly one type of challenge to design a concrete frame and post-tensioned floor system to meet structural code requirements and adequately resist and transfer required gravity and lateral loads. Yet it’s another type of challenge entirely to design a plan to make that happen. From specifying and erecting cranes and formwork to acquiring and maneuvering materials and equipment to sequencing and scheduling crews and trade partners, so much design and problem solving goes into making construction happen…and even more when things don’t go as planned (which often happens).

So, in honor of Construction Appreciation Week 2022, we’d like to give a shoutout to one of our favorite construction partners, Flintco!

With the ribbon cutting scheduled for September 26, 2022, Flintco and Wallace are set to wrap up construction at one of Tulsa's newest additions to the skyline, 222 North Detroit. The 11-story mixed-use building is an eye-catching, central anchor on the north end of downtown Tulsa, bridging the rapidly evolving Tulsa Arts and Greenwood districts. An impressive arched breezeway connects Reconciliation Park, Greenwood Rising, and ONEOK Field on the east to OKPOP, Cain’s Ballroom, the Bob Dylan Center, and more on the west.

As always, no building comes together without its share of construction challenges. In the case of 222 North Detroit, Flintco was faced with transforming an urban city block into a two-story below-grade parking garage topped by an 11-story concrete structure with brick and glass facade, while incorporating 16 completely unique post-tensioned floors and a five-story breezeway. Additionally, with ground breaking occurring in fall of 2019, Flintco dealt with the full gamut of pandemic-induced labor and supply chain issues throughout the life of the project.

With the advances in BIM, 3D scanning, drones, AI software, and more over the past 20 years, contractors have access to more revolutionary technology than ever that can help them design solutions to the logistical challenges that get thrown their way. In fact, in order for contractors to stay competitive and relevant, investing in construction technology and exploring innovative options isn’t a maybe – it’s a must.

But the contractors who are truly making the most of this age of technology aren’t the ones who are just investing, they’re the ones who are constantly looking for creative ways to apply different technologies to create more efficient job sites, condensed timelines, and safer work environments. This is where Flintco excels.

We caught up with John Bonner, Senior Project Manager at Flintco, to learn a little more about the construction technology Flintco uses and how he and his team approached some of the challenges on 222 North Detroit:

Flintco used drones and a program called Drone Deploy to periodically collect aerial data and create orthomosaic images of construction progress. At each stage, they could then overlay BIM plans to verify building components (footings, core walls, columns, etc) were located as specified.

Before pouring post-tensioned slabs, Flintco would document strand layouts with 3D photos. These measurable photos were linked to exact plan locations through a software called StructionSite. During later stages of construction, Flintco could quickly pull up pre-pour photos to use in conjunction with ground-penetrating radar (GPR) to verify strand locations prior to coring openings or installing supports.

BIM for Prefab Components

To save time and headaches in the field, Flintco relied on a streamlined prefab process for the plumbing and hydronic piping in lieu of field fabricating the assemblies from scratch. When it came time to install mechanical systems, Action Mechanical fabricated entire pipe sections correlated to the LOD 350 model and shipped them to the site. Once on site, crew members could scan a number and see in the model exactly where each section needed to be installed, making these system installations a snap.

So with all of the new and varied construction tech inundating the industry, we were curious: what technology or process has Flintco found to create the most value for their clients?

In Bonner’s opinion, it’s laser scanning.

“Laser scanning is a useful tool for us in being able to see if there's any discrepancy between the model and the field. Obviously, BIM coordination has always been there. I think it's a great, great tool, and I've seen a really big benefit in that. However, a laser scan really bridges the gap between the field and the model.”

In targeted applications, 3D point clouds can provide deeper insights than 2D drone imagery when correlating field work to the model, especially when dealing with elevations. In addition to verifying building component layout and installation, laser scanning can also be used to solve broader, logistical issues, like looking at how construction equipment, current site components, and the proposed building will mesh together.

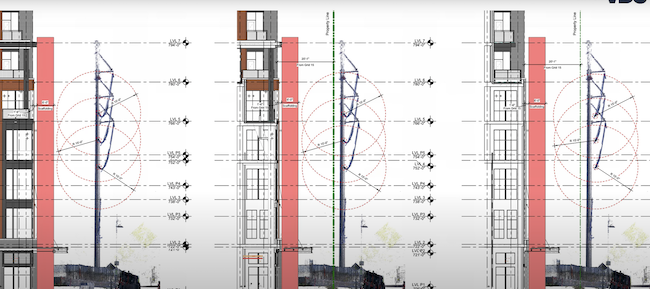

In the case of 222 North Detroit, Flintco and their Virtual Design and Construction (VDC) team used laser scanning to assess existing site features to help ensure a safe jobsite. By scanning existing high voltage power lines and then accurately locating the poles and lines in the model, the team could see exactly how the utilities would line up with the future building and scaffolding. This process allowed Flintco to determine early on that the lines would be too close per OSHA regulations. Thanks to some forward-thinking and the VDC team’s laser scan assessment, Flintco had plenty of time to work with the owner to relocate the lines and avoid potential safety issues or delays.

To see a full breakdown, check out Flintco’s video describing their challenge and solution here.

So do you still think “design” and “problem solving” are reserved for engineering? While those of us at Wallace Design Collective enjoy our engineering design work, we have a lot of respect for the problem solving skills of our partners in the field. They’re constantly thinking on their feet and finding innovative ways to use technology to tackle the logistical challenges that come with making our visions a reality.

So if you’re a student or young professional who is tech-minded and likes problem solving, but you’re not sure if traditional engineering design is quite right for you…have you ever considered construction?

“If you're really into planning, strategy, and teamwork, [construction] is really something that you'd want to do,” says Bonner. “I’m not saying that those aren’t on the engineering side, but the construction side of it, there's a lot of moving pieces, and if you like working through situations and challenges, it's really a good industry for you.”

Thanks, Flintco – and all of our contractors – for what you do! See you in the field!

There are no comments.